Maximize the benefits of MEP BIM Modeling Services with best practices! Learn how to streamline workflows, reduce costs, and improve the results.

MEP BIM modeling has been around for several decades, and it involves using Building Information Modeling (BIM) software to design and coordinate mechanical, electrical, and plumbing systems in buildings.

Early Days of MEP BIM

In the early days of BIM, MEP systems were often designed using 2D CAD software. However, as BIM software became more advanced, MEP professionals began to see the benefits of using 3D modeling tools to create more accurate and efficient designs.

Key Advantage of MEP BIM Modeling

One of the key advantages of MEP BIM modeling is its ability to help identify clashes and conflicts between different systems before construction begins. This can save time and money by reducing the need for rework and change orders.

Over the years, MEP BIM Modeling Services has continued to evolve and improve. Today, many BIM software packages include tools specifically designed for MEP professionals, such as parametric HVAC and electrical components, energy analysis tools, and clash detection features.

As the construction industry continues to embrace BIM, MEP professionals are likely to play an increasingly important role in the design and construction process.

By using BIM to create more accurate, efficient, and sustainable MEP Designs, they can help ensure that buildings are safe, functional, and energy-efficient for years to come.

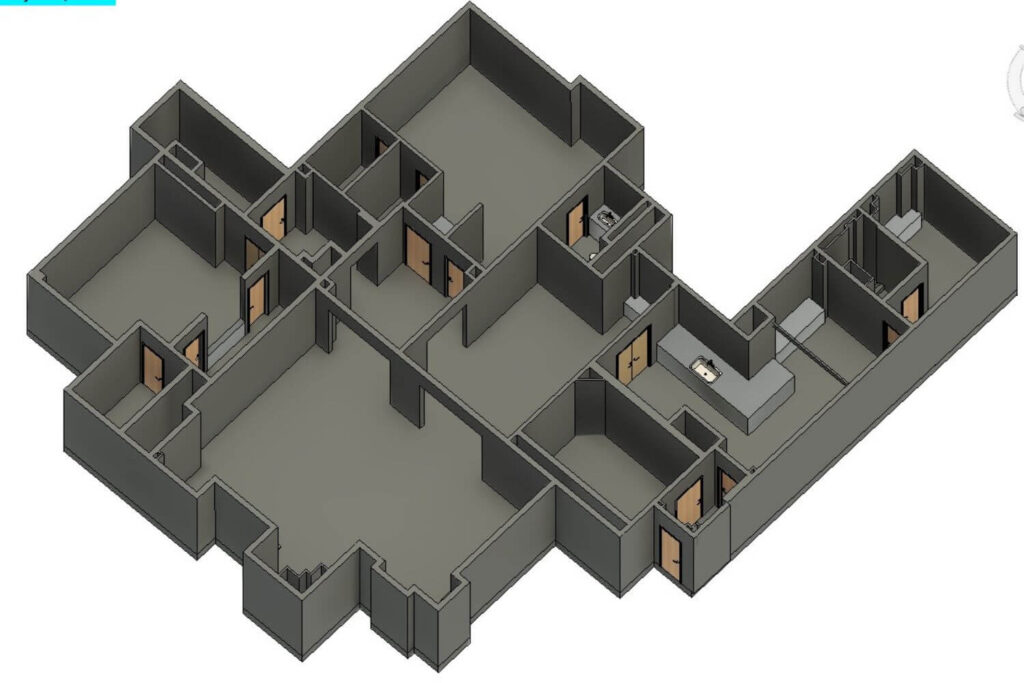

Understanding 3D MEP Modeling

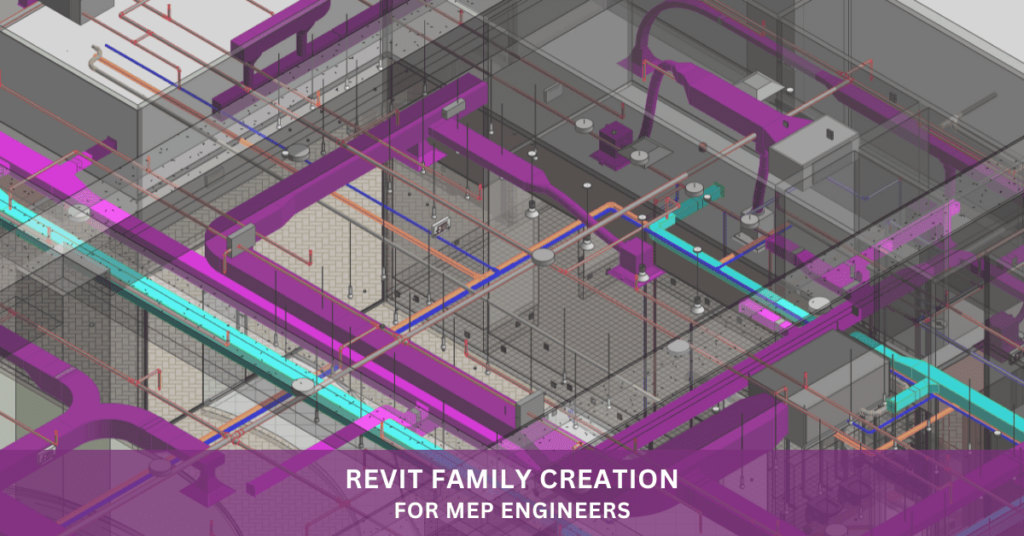

MEP modeling is a process of creating a digital representation of mechanical, electrical, and plumbing systems in buildings using specialized software.

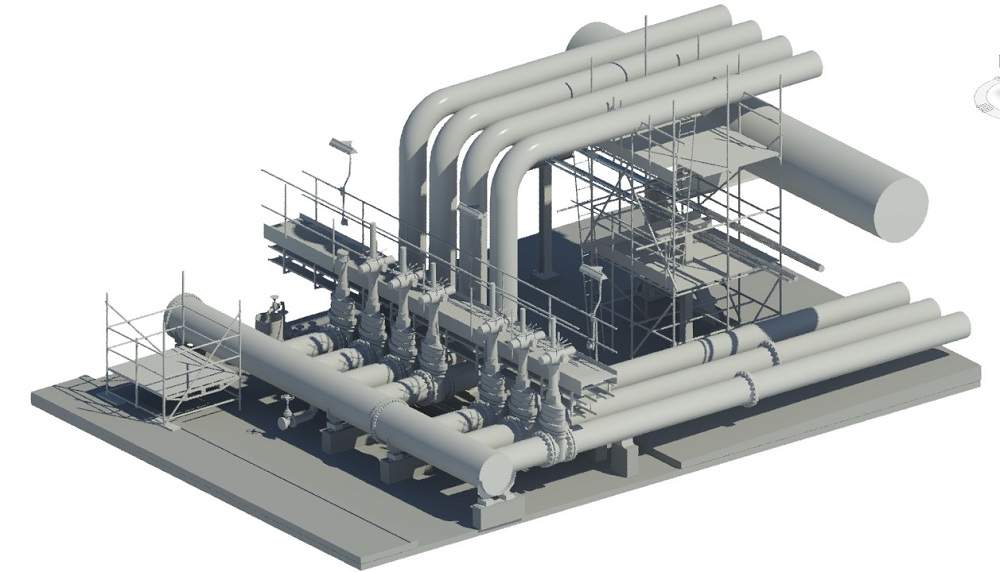

It allows construction professionals to create highly detailed and accurate 3D models of MEP systems, including ductwork, piping, electrical conduits, and other components.

One of the primary advantages of MEP BIM modeling services is its ability to identify potential clashes and conflicts between different systems before construction begins.

This helps to reduce errors, delays, and rework during the construction process, ultimately saving time and money.

In addition to clash detection, MEP BIM services also allow for more efficient design and coordination of MEP systems, as well as improved visualization and communication among project stakeholders. It can also help to improve energy efficiency and sustainability by allowing for more precise sizing and placement of MEP components.

Overall, MEP modeling has become an essential tool in the construction industry, enabling MEP professionals to create more accurate, efficient, and sustainable building designs.

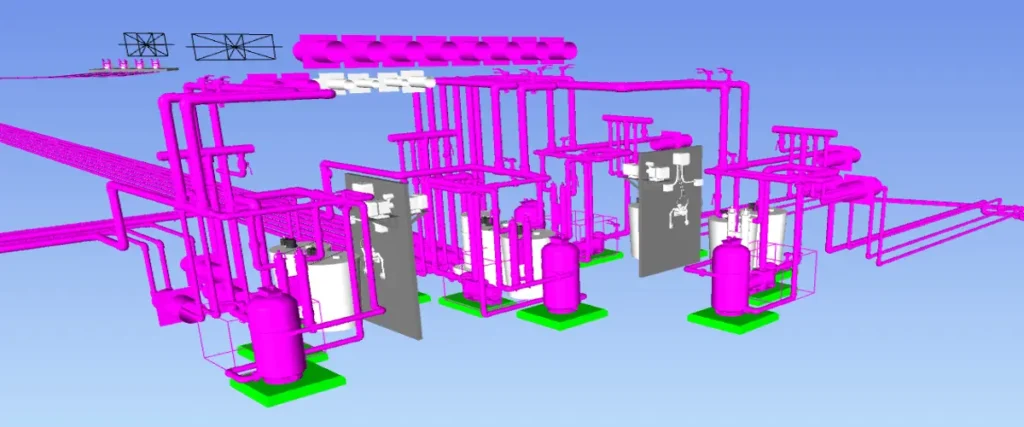

Applications of MEP BIM Modeling Services

MEP BIM modeling Services has numerous applications in the construction industry, including:

- Efficient design and coordination of mechanical, electrical, and plumbing systems

- Identification and resolution of clashes and conflicts between different systems

- Improved visualization and communication among project stakeholders

- Enhanced energy efficiency and sustainability through precise sizing and placement of MEP components

- Accurate and detailed quantity takeoff and cost estimation for MEP systems

Best Practices for MEP BIM Modeling Services

MEP BIM modeling is a powerful tool for designing and coordinating mechanical, electrical, and plumbing systems in buildings.

By creating a digital representation of these systems, MEP professionals can identify potential issues and conflicts before construction begins, leading to a more efficient and cost-effective construction process.

Here are six best practices for applying MEP BIM Modeling Services in the construction design process:

1. Begin with a Clear Understanding of Project Goals and Requirements

Before beginning the MEP BIM Modeling process, it’s important to have a clear understanding of the project’s goals, requirements, and constraints. This can help ensure that the modeling process is focused and efficient.

For example, if the project goal is to create a highly energy-efficient building, the MEP design should prioritize systems and components that support this goal.

2. Use A Standardized Naming Convention for MEP BIM Modeling

A standardized naming convention can help ensure consistency and clarity throughout the modeling process. This can include naming conventions for MEP components, equipment, and systems.

A standardized naming convention can also help ensure that all stakeholders are using the same terminology, reducing confusion and errors.

3. Use Parametric Families for MEP BIM Modeling Services

Parametric families are 3D objects in BIM software that can be customized and adjusted based on specific project requirements.

Using parametric families can help ensure that MEP components are consistent in size, shape, and performance throughout the project. This can save time and reduce errors during the modeling process.

4. Collaborate with other project stakeholders using MEP BIM Services

Collaboration is essential in the construction design process. MEP professionals should work closely with architects, engineers, contractors, and other stakeholders to ensure the design meets everyone’s needs.

Collaboration can include regular meetings, communication via email or phone, and the use of collaboration software.

5. Use Clash Detection to Identify Conflicts in MEP BIM Models

Clash detection is a process in which the MEP BIM model is reviewed to identify potential conflicts between different systems, such as ductwork and piping.

By identifying and resolving these conflicts before construction begins, the project can be completed more efficiently and with fewer errors. Clash detection can be automated using BIM software, making it a fast and efficient process.

6. Continuously Review and Update the Model

The MEP BIM model should be continuously reviewed and updated throughout the construction process to ensure that it remains accurate and up-to-date.

This can help avoid errors and ensure the project is completed on time and within budget. Updating the model can include adding new components, adjusting existing ones, and making changes based on feedback from other stakeholders.

Get FREE Quote

For BIM Services for Your Project

Conclusion

Applying MEP BIM Modeling Services in the construction design process involves beginning with a clear understanding of project goals and requirements, using a standardized naming convention, using parametric families for MEP components, collaborating with other project stakeholders, using clash detection to identify conflicts, and continuously reviewing and updating the model.

There are many reasons why using MEP BIM Services is beneficial for construction projects such as; improved visualization, efficient design, and coordination, clash resolution, quantity takeoffs, etc. MEP BIM Modeling Services help construction professionals to develop well-coordinated designs.

By following these best practices, MEP professionals can create more accurate, efficient, and cost-effective MEP designs, leading to successful construction projects.

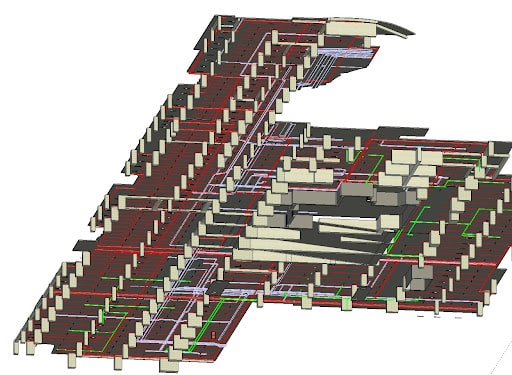

Our Recent Projects on BIM Services

Related Posts

Share Via

Tags

- 3d mep, bim and mep, BIM for MEP, BIM MEP Engineer, bim mep services, bim revit mep, mechanical bim services, mep bim modeling, mep bim modeling in uk, mep bim modeling in usa, mep bim modeling services, mep bim services, mep in bim, mep in revit, mep modeling, revit mep, revit mep bim, revit mep model

Devashish Sharma

Devashish is Founder/Director at Cresire where he leads BIM services. He holds a bachelor’s degree in Civil Engineering from the University of Sheffield and an MSc in Construction Project Management from The University of the West of England. His vision behind CRESIRE is to provide BIM services, adhering to best practices and procedures, to global customers, helping customers to save extensive production costs and overruns.